Chromalox OCE open coil element large-tank electric heaters installed inside 2- or 3-inch Schedule 40 NPS pipe provide uniform heat over a large surface area. Fast Delivery of Fuels Lubricants Chemicals Equipment More.

Steam heating coils should generally have a gradual fall from the inlet to the outlet to ensure that condensate runs toward the outlet and does not collect in the bottom of the coil.

. Energy Consumption of Tanks Vats. Our Tank Heating Coils are Custom Designed to Client Specifications AHC storage tank heating coils are built to match your specific criteria and meet your facilitys unique needs. How to Design Tank Heating Coils_Parte2.

StorMaxx CTEC solar hot water storage tanks are large 211 gallon low pressure solar thermal storage tanks. While using the formula AQULMTD I assumed the coil geometry based on some literature data of hot water diameter thickness velocity of the hot water and then I had to determine the overall heat transfer coefficient 1U 1ho 1h1 xk. Ad We Make Standard Copper TubeAluminum Fin Commercial Coils Build Heavy Industrial Coils.

The heating and cooling media can flow through a coil immersed in the liquid as shown in Figure 1. Any steam heating system design must consider the nature of the liquid. 1 corrugated stainless steel coil heat exchanger for DHW.

This web application calculate the area length required for an internal coil carrying condensing steam for heating the tank contents. Tank-Type Storage Tanks Ideal for businesses using large volumes of water in short periods of time Rheem commercial storage tanks are manufactured from heavy-gauge steel using high-temperature porcelain enamel lining to protect all tank and coil components for. These heaters are designed with low watt density open coil heating elements for uniform heating of even the most temperature sensitive materials.

Keep these advantages and benefits of our unique tank heating coil designs in mind. CTEC tanks have three internal exchanger coils and enough insulation to earn them an R-value of 16. However i am unable to find any reference for designing a coil submerged in the tank.

Coils can be schedule 40 schedule 80 or other thickness as required. Q MCp T. Actually i got many references for heating coil design for tank with agitator.

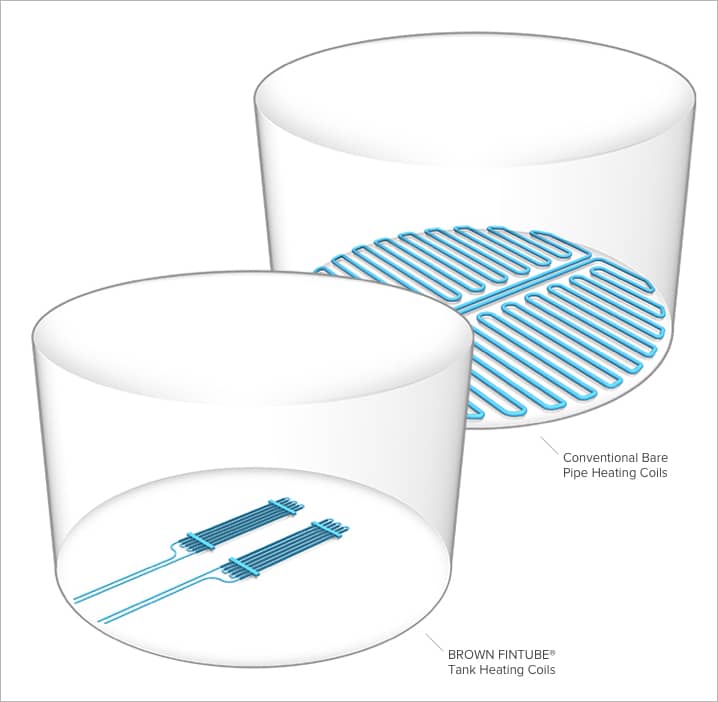

This heat requirement measure does not indicate how quickly the tank will be heated however. Tank heating coils can be designed to fit through existing manways. Fin and coil material can be carbon steel or a variety of stainless steel and other metals.

Process operation parameters. I am currently sizing a hot-water heating coil for an already sized storage tank the fluid inside the tank is stationary. The following data must be gathered in order to perform the calculation.

Get the design data. Ad Overhead Tanks Frac Tanks Aviation ISO Tanks. The proper design of heating coils for a bulk liquid storage tank depends on many factors.

Deionized water absorbs heat from the fuel cell and is then pumped through the. Most American Heating Company tank coils are horizontal and employ solid helically-wound fins. Condensate drainage and cleaning maintenance.

D903XLS Storage Tank Heating Design_ggggg. The overall heat transfer coefficient of the heating coil. The flow of heat into or out of the liquid involves unsteady or transient heat transfer.

Result For heating a batch with an internal coil with an isothermal heating medium following equation is applied. The tank is not supplied with agitator. Each coil is computer designed by our experienced engineering staff.

The heat exchange area of the heating coil. Tank coils are not generally used for the continuous heating or cooling of a flowing stream but are usually applied in the heating or cooling of a liquid contained in a tank on a batch basis. Q 7488 100 70 524160 Btus.

We Build Coils For All Applications Meeting Your Requirements Every Time. Area A MCm Uθln T1-t1 T1-t2 Area A 3259 ft² Heating Coil. INDEECO Electric Storage Tank Heaters are used to maintain or raise the temperature of gases and fluids in tanks from -300F to 1000F for a variety of applications and industries.

The storage tank and IHX coil are part of an integrated micro-combined heat and power micro- CHP system driven by a proton exchange membrane PEM fuel cell. Crude Oil Storage Tank Heating Coil. In theory if the tank were perfectly insulated and used 1 Btuhr for heating it would take 60 years to heat one tank.

Hello All I want to design a coil which is used in heating a amine solution in the tank. Possible liquid heatup time. Where a lift is unavoidable it should be designed to include a seal arrangement at the bottom of the lift and a small bore dip pipe as shown in Figure 2102.

2 bare tube steel coil heat exchangers. Sizing data of the heating coil. The heat exchanger involved in heating is an internal coil.

T 1 140 - 70 70F. Flexible Tank Heaters Chromalox FXTH flexible tank heaters provide low-watt-density heating for viscous materials such as asphalt fuel oil pitch and tar liquid sugar molasses lube oils linseed oil and other heat-sensitive. Heating Coil Design - posted in Process Heat Transfer.

The expected heat loss.

Thermal Oil Heaters For The Heating Of Storage Tanks In Ports Pirobloc

Tank Heaters Koch Heat Transfer

Different Ways Of Building Industrial Hot Oil Heaters Serpentine Vs Helical

Circulation Enhanced Tank Heating Using Shallow Profile Coil Bundles Springerlink

Study On Coil Optimization On The Basis Of Heating Effect And Effective Energy Evaluation During Oil Storage Process Sciencedirect

Asphalt Tank Steam Coil Lay Out Download Scientific Diagram

Benefits Of American Heating Company S Tank Heating Coil Design

0 comments

Post a Comment